The 1st September brought 6 vans full of 9 contractors to start work on our energy efficiency improvements. By day 2 we were up to 8 vans, and I have no idea how many people. The cacophony of SDS drills, impact drivers and slamming van doors was a bit overwhelming. You couldn’t go anywhere without getting in someone’s way, so I mainly hid out in the shepherd’s hut. Mr Wombat became a kind of default foreman, as although the individual trades were competent, the plumbers didn’t really collaborate with the electricians and the guys doing the insulation didn’t plan work with anyone else. Also, no one really seemed to grasp the implications of having a pump in a well feeding the house and therefore limiting the way pumps could be installed downstream if they removed the header tank as they originally planned. They did eventually concede that he probably knew what he was talking about, and there was less rework from that point on.

After a very full on week of chaos, we had a week’s respite in a cottage in the Lake District with friends and their dog. It was a nice change of scene, but we realised how much we’d become accustomed to our quiet corner of the world – there we SO MANY people! Even the smallest layby seems to have a RingGo app sign and 24/7 parking charges.

It was pretty showery all week, but we managed to fit in some lovely walks and I left everyone in bed on the best morning for a glorious solo swim in Buttermere before breakfast.

We were soon back to reality and glamping in the garden. Progress slowed a little after that first week. 8 vans became 2-4. Morale was not helped by the fact that a good proportion of the workforce were facing redundancy. We had a brief panic and researched ‘what happens if your ECO4 installer goes bust half way through the install’, but it seems that the business was just right-sizing itself for a reduction in funding and slowing private demand. Fewer staff across their existing jobs meant that attendance at our place was a little more sporadic, but steady progress was made.

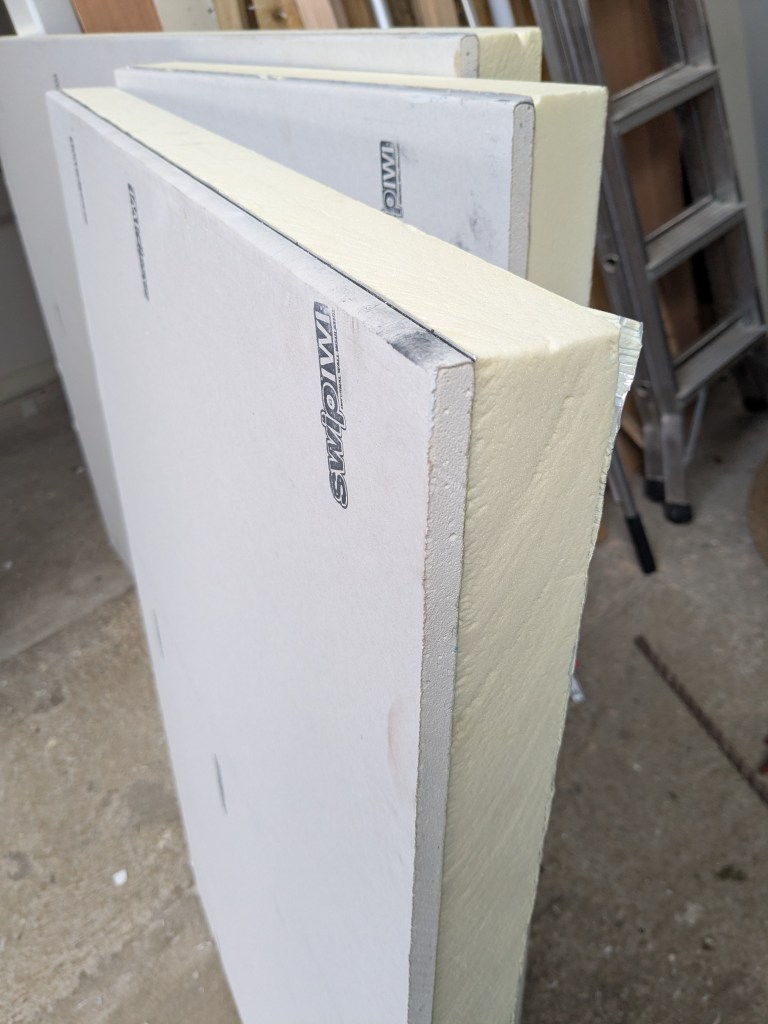

We didn’t want internal wall insulation on our solid walls downstairs, but we agreed to ‘room-in-roof’ insulation in the bedrooms upstairs. This consists of SWIP board on all the sloping ceilings – which is essentially foil backed rigid foam insulation board with plasterboard bonded to it. They also replaced the loft insulation above the small flat section of ceiling and fibre insulation at the gable ends. They would have just gone over the top of what was there, but we suspected there was old damp loft insulation right up against the underside of the roof under the plasterboard that we wanted to remove first, to improve ventilation.

We stripped it all back ourselves, removed the ancient rockwool, which wasn’t nearly as damp as we feared, but did contain quite a lot of bat poo. Removing all the plasterboard also gave us the chance to inspect the roof from inside. We had braced ourselves to discover all kinds of expensive horrors. In fact, it was in pretty good shape and we were surprised to find original sarking, having assumed the roof would have been replaced at some point in the last 250+ years. The boards are much wider and thicker than modern equivalents and you can still see some bark on waney edges! There were some modern alterations around the velux windows (most of which will need replacing fairly soon), and some evidence of historic woodworm, but thankfully nothing active or serious. We discovered that the original upstairs fireplace had been blocked up, which was a shame as we knew there had to be one behind the plasterboard on this wall somewhere. We would like to lime plaster this gable end wall at some point, so we may try to open it up then.

The ventilation behind the insulation is now much improved all round and the the room should be much warmer.

While one team were tackling the insulation upstairs, the plumbers installed the heat pump and hot water cylinder quickly, but it took a little longer to be commissioned. The new hot water cylinder wouldn’t fit in the cupboard upstairs that we had so carefully fitted the replacement stainless tank into in July. We elected to fit it in the corner of the kitchen, the other side of the wall from the heat pump. This unfortunately meant a lot more disruption, and ripping out the only wall cupboards we had, in an already storage-deficient kitchen. The plumber did an amazing job of routing the pipework close to the cylinder to leave space for the washing machine next to it, on the only wall with drainage. I am sure he went home and complained to his family about how awkward and time consuming it was, but we were very grateful.

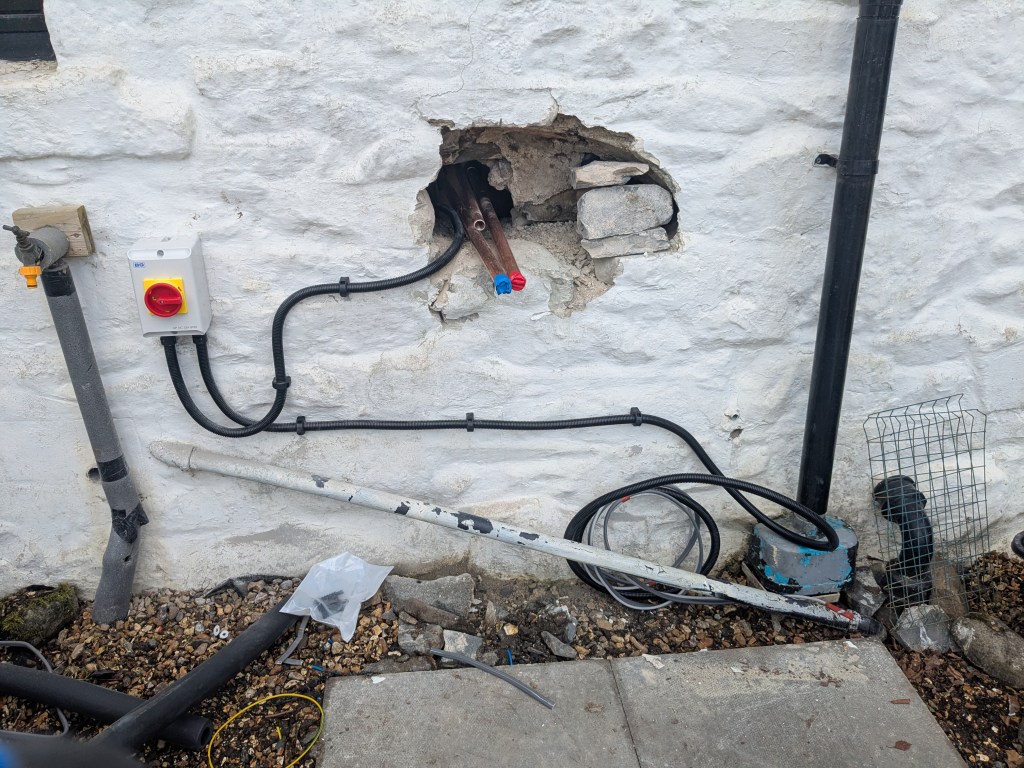

They made a larger-than-planned hole in the wall between the cylinder and heat pump, when they had to remove several large granite blocks after trying to cut through for several hours didn’t get them very far. I stopped them filling the hole with cement, and am half way through filling the void with stone and lime mortar. A tricky job, when you can only access a half meter thick wall from the outside. My arms are just long enough, but I am having to do it by feel and the restricted space behind the heat pump makes it a bit of a contortionist’s trick.

The arrival of the heat pump in the first week meant the Rayburn was all but redundant. We never ran it 24/7 as it was a fairly modern oil model and heated up quickly. This meant it didn’t make financial sense to run it all the time and it could do the heating and hot water on a timer like a normal boiler. I didn’t know it at the time, but January’s oil tank fill up would turn out to be the last one ever.

The large stainless flue through the roof was also now redundant. We suggested they replace it with a vent tile for the kitchen and bathroom extractors that were being fitted as part of the deal. Thankfully they agreed that was a good idea, and the roof now looks much tidier and they haven’t had to punch too many additional holes in the oldest part of the house. We are also grateful not to be left with a metal tube in our kitchen ceiling, open directly to outside.

They did remove a small amount of original floorboard from the coomb space upstairs when replacing plumbing and insulating. Whilst not ideal, we were careful to save the wood. In fact, we saved a lot that the installers put out for rubbish. Not just stuff stripped out of the house to make way for new (including a 2 month old stainless hot water tank and new towel radiator that turned out to be too small for their calculations). They were incredibly wasteful with materials. We went full-on womble in the evenings after they left, sorting through the bags left out for their waste van to collect every few days. We now not only have a good stash of scrap copper to take to the local scrap dealer, but also managed to rescue a lot of brand new pipe fittings, a good length of data cable, bags of unused cable glands and half full boxes of screws.

Remember that in-line extractor we installed in the wet room ceiling in June? That was removed in favour of a humidity controlled one.

Once we are a bit more organised, I’ll get the better things (that we can’t use elsewhere) advertised for sale. Let me know if you’re in the market for a nearly new stainless steel hot water tank and can collect from SW Scotland 🤣.

I looked into selling the Rayburn, but there’s not much demand for oil fired models (and lots of people taking them out). Couple that with the 350kg weight and moving the thing ourselves wasn’t appealing. It was mentioned to us that someone who is in the process of making an old farmhouse up the road, habitable again, might want it. We were happy to give it away on the proviso that they come and get it. A few days later, 4 big blokes turned up to move it out of the house, rolled on cut up lengths of fence post. It was transported on a telehandler to is new home a mile or so up the road. Definitely the end of an era, but the second hand electric oven we are currently using is so much more predictable.

The batteries and solar were up and running by the end of the month, just intime for the weather to turn. When the sun did appear, it was quite low in the sky. As we have an EV tariff, we are able to charge over night for 8.5p per kWh, and use that during the day instead of full price power. We plan to expand our battery capacity as soon as the current install is officially signed off. We currently have 10.6KWh capacity and will probably double it. We have an 11 panel solar array, which should generate up to 4.5kW, but I think the best we have seen so far is approx 3.7kW, and its only going to get worse until the spring. We may well increase that in the spring too.

As you can probably guess by the lateness of the update, and how much has been going on this (last) month, the performance of the freedom fund has been far from our minds in the last few weeks. We set aside a morning to do the monthly update, and were pleasantly surprised.

Freedom fund value – £1,427,824 (up over 20k on last month)

Expenditure – £2,511.03 (or a 2.11% withdrawal rate) including renovation costs, or £2,412.24 (or a 2.03% withdrawal rate) without renovation costs

Earned income – £0

Despite a week away and more eating out than usual, September was not an expensive month, and came in slightly below what I am expecting to be average for 2025. Van insurance and home insurance renewal were the biggest individual expenses. Luckily van insurance is Mr Wombat’s responsibility, so I only had one set of insurance comparisons to trawl through. In the last few years, comparing options has become more important than ever, as the variation in cover and cost is huge. We have never claimed on home insurance in the 24 years we have had it, and wouldn’t unless there was a major disaster, so I was able to decline a lot of unnecessary add-ons. Another case of financial independence saving us money, as we would be able to cover accidental damage repairs without needing to claim. Not everyone has that luxury. The fact that we have slowly upskilled ourselves over the years with DIY, means we can handle a lot of repairs ourselves, making that a realistic strategy for us. I appreciate that isn’t true for everyone.

Reduce plastic waste by making one change every month – Nothing to report in September, and October will be the same. Maybe by November life will feel a bit more in control, and I’ll be able to focus on this again.

Do something creative every month – I made time for 2 workshops in September. Whilst in Cumbria with a crafty friend, we both spent the day learning how to create mosaics. I was very pleased with how mine turned out. It is based on a photo of a Scottish Blackface ram I took a couple of years ago. I ran out of time on the day, but I brought home some blue pieces and tile adhesive to finish the background (once I have a bench or table accessible to do it!)

The other workshop was a very informal evening affair hosted by one of my local art group. She is a (very talented) textile artist, but sewing really isn’t a skill of mine. I was really only in it for the social aspect. She showed us all how to make a ‘memory pocket’ from her hand dyed fabrics – a small book-like fabric creation with a pocket inside to hold a card with something written on it. I was pleasantly surprised that mine wasn’t a total disaster.

Record the birds and mammals spotted around the house each month – With all our belongings packed away, I failed to record September’s comings and goings, but we did have 2 red squirrel sightings at the end of the month, which is quite exciting. I hope keeping the garden as a small curated wilderness encourages them to return.

And finally, a few from the lake district (including Buttermere in the morning of my swim), some of the explosion of mushrooms found in local woodland in September, hawthorn berries that I turned into ketchup, and a rather atmospheric misty morning swim.